6. Silver Gelatin P.O.P. Collaborative Research Project — Recipe #1: KCl/Citric Acid, p.1 |

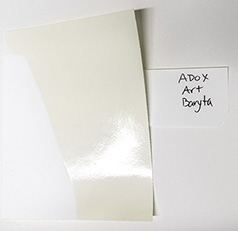

ONE THING LEADS TO ANOTHER I'll start with a tale of research, and how questions are generated. I've made this recipe dozens of times. It is the one in my book on making paper. The recipe was on TLF before I put it in my Focal book on paper making. The links aren't available on the current TLF index, but the Way-Back Machine has them, so here is the page with the recipe. POP isn't my go-to for my personal art, but I'm fascinated by a process that can be both technologically simple and a challenging craft. Because I'm familiar with the recipe, it seems like a logical starting point for a POP research project. I've mainly used it with Rives BFK, so trying different papers is a great first question. How do different papers look and react? This naturally leads to a follow-up question. Does the same paper react the same with different POP formulations? Left: 4x5 contact print on ADOX Art Baryta, developed in plain hypo (more about that later), untoned. There were seven papers I had in mind to try. The challenge of any rigorous comparison is being absolutely certain each sheet of paper gets coated with emulsion with identical characteristics. The only way I know to do this without resorting to elaborate lab equipment is to make a large enough recipe to coat all the paper in the same session. A single recipe won't do. A double recipe would also give me enough sheets to test storage/keeping characteristics. I'd planned on splitting the paper into three parts and keeping one at room temperature, one in the refrigerator, and one in the freezer. Alas. |

|

A Cascade of Variables It should have been simple. I doubled the recipe (variation #1) and had the KCl and gelatin mixed and partly melted when my dog decided in no uncertain terms that it was time to go for a walk. I hadn't mixed the silver nitrate yet so I pulled the gelatin out of the water bath. By the time we got back, I was done for the day. I considered throwing out the gelatin and KCl and starting over, but I decided instead to refrigerate what I had mixed up and use it the next day (variation #2). The next day, I remelted the gelatin/KCl and mixed up the rest of the chemistry. The recipe calls for a 30 minute ripening. I always prep the paper for wet coating while the emulsion is ripening. I used the same tray of distilled water to soak seven different papers (variation #3). About 10 minutes into the ripening, I got a phone call I wanted to take. It lasted long enough that by the time I'd finished getting the paper ready to coat, the emulsion had been ripening for 45 minutes (variation #4). I live on the Oregon Coast. The climate is cool and humid so I need supplemental heat in the darkroom if I want paper to dry in a reasonable amount of time. I have a small convection space heater in the darkroom. I always set it as low as it goes when I dry paper or film. However, our weather was very cold a couple of weeks ago and I had set the heater at a higher temperature while I cleaned the darkroom. I neglected to turn the heat back down, so the paper dried at about 85F (variation #5). |

|

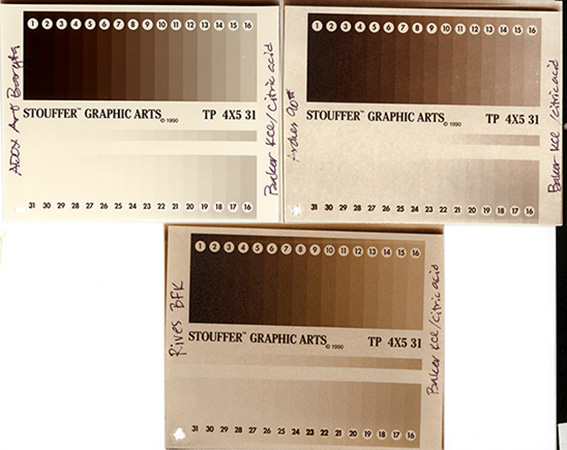

A Recipe Overwhelmed by One Crucial Variable or a Perfect Storm of Many? Long story short (too late?). The paper was fogged. Some more than others. The ADOX Art Baryta was least of all. There is a small piece of each uncoated paper next to its coated mate for a color comparison. Each variable could lead down a research trail. 1. What factors might have changed with a recipe doubling? How much can a recipe be scaled up before its characteristics change? 2. Can the recipe be held under refrigeration at stage before coating? The answers to 1 and 2 could help address whether or not largescale POP production is feasible. Do any of the papers have components that fog emulsion? If an offending component can leach out of the paper, can it be soaked out before coating to make the paper safer to coat on? If a paper has a component which potentially causes fog, could it cause the deterioration of a print over time? Ripening time is a key emulsion variable. At a specific time/temperature an emulsion reaches it's peak speed. Beyond that point the emulsion can (and usually does) start to fog. The aspirational goal is to ripen right up to top speed and no further. With paper, speed is far less an issue than a clean (completely unfogged) emulsion. What is often overlooked is that ripening continues after coating. It slows down after the emulsion is dry but never really stops. Some emulsions fog much sooner in storage than others. POP is notorious for a short storage life. When I both over-ripened the emulsion before coating and then dried the paper in a very warm room, I almost certainly contributed to the fog. There are several questions generated. What are the time and temperature of ripening end points for a successful POP emulsion? Are they different for different POP recipe formulations? Could reducing the time and/or temperature of the emulsion ripening result in longer dry paper storage life?

|

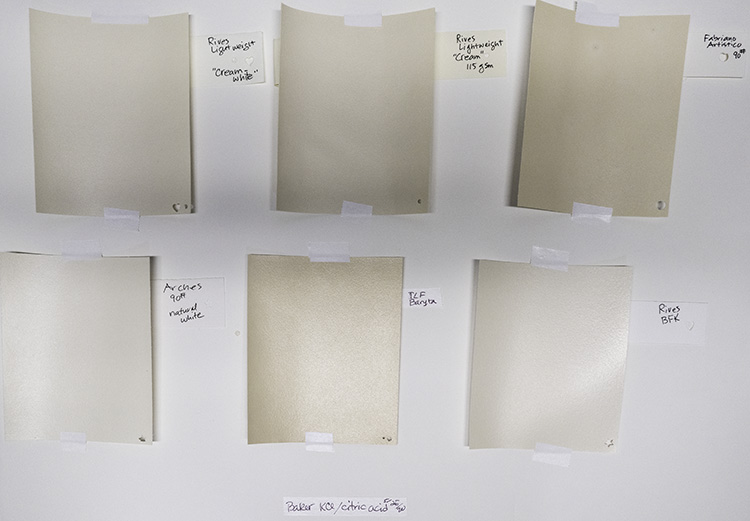

Above, clockwise from upper left: Rives Lightweight, cream-white; Rives Lightweight, cream; Fabriano Artistico 90 lb, traditional white; Rives BFK; TLF Baryta; Arches 90 lb, natural white. (not shown: ADOX Art Baryta) Photographic gelatin is not colorless, although some brands have more color than others. I used Photographers' Formulary gelatin for this recipe. A year or two ago they changed the gelatin they sold. It used to be large granules with less color. Here's a puzzle: Unlike with the other paper, the color of the emulsion on the ADOX paper is almost the same as the gelatin. The color of the Arches watercolor paper is only a little darker. What protected the ADOX paper, and to a lesser extent the Arches paper, from fogging? What differences are there among the different brands of photographic gelatins? |

ADOX Art Baryta The ADOX paper has a high gloss finish. It looks like an RC (resin-coated) print. That's not my favorite look, but it must be admitted that all the detail of a negative is preserved. Nothing is lost because of paper texture. Arches 90 lb is a close second. The details of the step tablet are better represented than appears from a flatbed scan of the print. Rives BFK is normally an excellent paper, but this time it badly fogged, more so than was suggested by the unexposed paper. Paper choice is highly personal. One of the reasons I choose to make my own printing paper is because I love the wealth of textures that were available in the various discontinued legacy papers. Most of them can be closely duplicated with today's watercolor papers. |

|

|

Above left: ADOX Art Baryta, wet paper coated. |

|

ADOX Art Baryta coated beautifully with the wet paper coating method. I decided to sacrifice an additional sheet to see if it was suitable for dry paper coating. The paper feels fairly heavy. I thought it worth the risk (the paper is expensive). The emulsion went down smoothly — no skips or bubbles, but it immediately washboarded along a slight angle to the long edge of the paper. When it was dry, I could still see the ridges, but the coating looked OK. The print says different. The thin spots where the paper swelled and raised up, shedding the emulsion before it could dry, are very visible. A high gloss surface is a challenge to spot. The image at the top of this page is the retouched wet-coated print. The work is not invisible. Denise Ross |

|

| < Color and Curves Reading #2 > |