7. Getting Started—Paper Coating |

|

Wet paper coating is about as easy and foolproof as coating gets. I recommend it over dry paper coating as a place to start. |

|

Wet Paper Coating with Guide Bars January 2025 Update: When this tutorial was originally written in January 2013, I wasn't yet coating with emulsion guide bars. Today, I almost exclusively coat on wet paper with guide bars. The complete instructions are here. Instructions for preparing a glass coating rod for silver gelatin emulsion coating are here. |

|

Free-Form Coating (3/25: Modified from the 2013 version) Free-form coating is a quick way to get started with coating. It encompasses the same basic ideas and skills of coating with guide bars. All you need is a glass surface and a prepared puddle pusher/glass coating rod. The difference is pretty much summed up in the name. In its simplest form, it is identical to coating with guide bars – without the guide bars. If you haven’t already, please read about coating with guide bars and then return here.

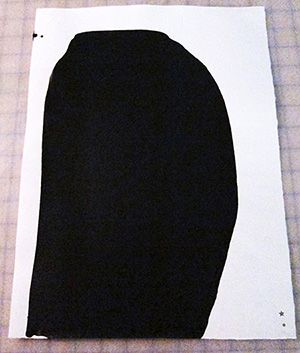

On the left is an actual exposed and processed full sheet. It was coated without any overflow off the ends of the Puddle Pusher so the full sheet is good-to-print. The example of the blue "emulsion" shows what happens when emulsion flows past the ends of the Puddle Pusher during coating. You can see the dark blue of the extra thick areas along the edges. The implications of this are explained below in "Troubleshooting." You’ll need to play with coating for a bit to decide the right coating temperature of the emulsion, the right amount of emulsion to pour, and the right speed to pull the puddle pusher.

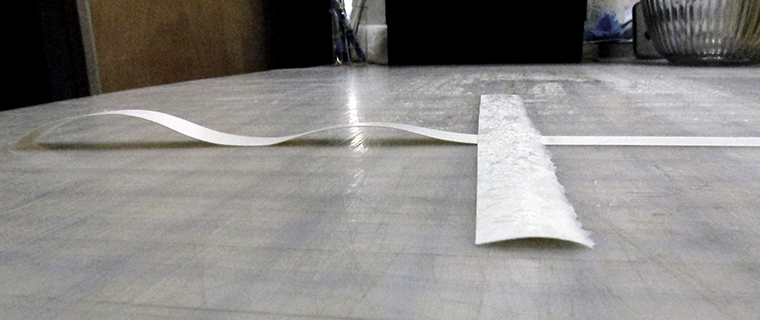

Dry Paper Coating Wet paper coating eliminates the biggest drawback of coating on dry paper – buckling. Paper buckling happens when the paper gets wet and swells. The wet emulsion flows off hills and fills valleys. The result is an ugly patchwork of too-thin and too-thick emulsion. It’s pretty much unusable. However, dry paper coating is perhaps the least “fussy” of the coating techniques. It is certainly worth trying to see if it’s your preference. The good news that we can use to our advantage is the tendency of most watercolor papers to curl when they get wet. This requires understanding and respecting the grain of the paper and coating in the right direction. I recommend finding a good article on paper grain. The websites of most of the major paper manufacturers have some excellent information. Paper cups along the long grain and washboards along the cross/short grain. It’s easy to test. Cut a strip from along one side of a sheet and one from either the top or bottom. The grains of two strips run perpendicular to each other. Make a note on each to remind you which is which.

Quickly dip each in water and then gently squeegee between your index and middle fingers. Alternatively, you can mist the strips with water. This is the best technique with the lighter weight papers. Place the strips on a waterproof flat surface. Almost immediately, one will cup and the other washboard. You’ve determined the grain of your paper. You will coat along the direction that cups.

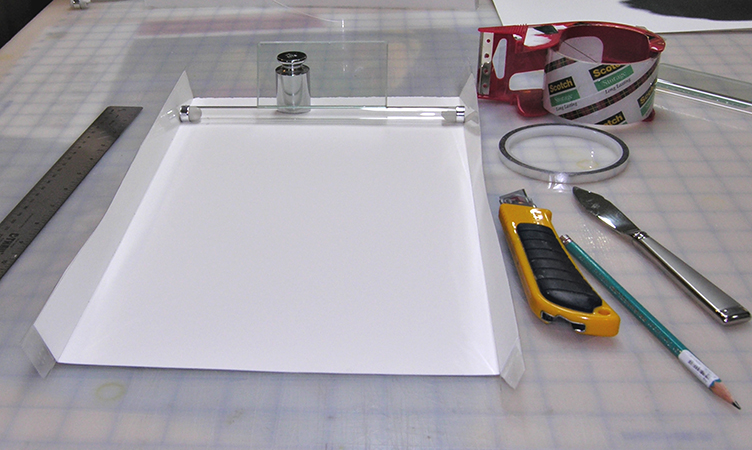

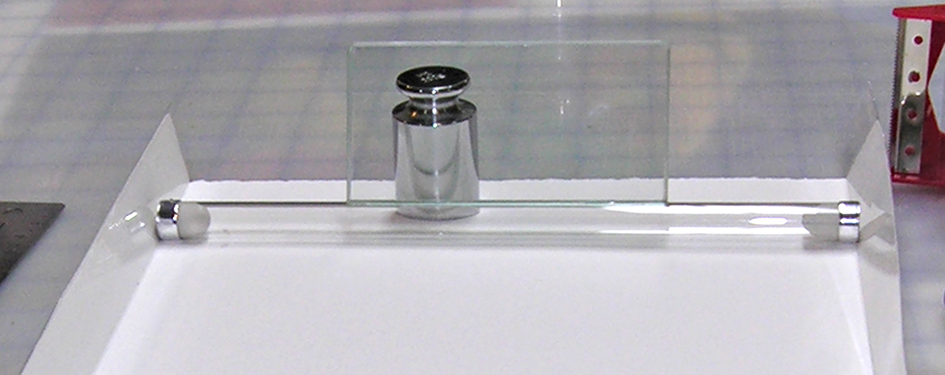

Prepare your paper for coating. Lay your prepared puddle pusher/glass coating rod on a piece of watercolor paper, at the top of the sheet. Make a pencil mark at each end of the rod. Repeat at the bottom of the sheet. Set the puddle pusher aside. Line up a straightedge along the top and bottom marks on one side. Score (dent) the paper with a blunt knife. I have a butter knife that’s perfect. You don’t want to cut the paper. Repeat on the other side. Fold the paper up along the scored lines on both sides. You’ve made a paper coating trough. Optionally, you can cover the inside of the upturned edges with plastic tape. Repeat this for as many sheets of paper as you’re planning on coating. You will run the emulsion down the length of the paper with the turned-up edges acting just like the guide bars used in wet paper coating. The difference is that the paper will not stay flat. If you’ve identified the grain correctly, the paper will cup. When this happens, the wet emulsion will drain to the sides. This requires that the temperature/viscosity of the emulsion closely calibrated so that too much doesn’t run off. This will require a bit of trial and error.

Depending on the paper, it may need help to maintain its cup until the emulsion sets up. A piece of pool noodle carefully shoved under the cup as soon as it forms works well. If you’ve made a trough with the grain running the wrong way, it will washboard instead of cupping, ruining the coating. When the emulsion is dry, cut off the edges and the strips of thicker emulsion that settled along the hinges. |

|

Troubleshooting

You can't make a coating trough against the grain of the paper. |

If emulsion is too warm when it's applied, it looks just like cooking oil poured into a very hot pan. It's easy to see after the paper is exposed and processed. There are irregular islands of low density and matte surface sheen surrounded by deep black. On the back of the sheet there are black spots where the emulsion soaked through the paper. Fortunately, you can easily see the problem under safelight while the emulsion is still wet, so it is easy to adjust your coating temperature before you go on to coat your next sheet. If you are coating on thicker paper, the emulsion won't soak through. The front surface will be more uniformly dull — a problem that's harder to spot during coating. If you are new to emulsion making, or if you are developing a new recipe, it is easy to mistake the effect of too-thin coating with having a poor maximum black emulsion (a.k.a. low vigor in the old literature). |

Applying emulsion that is too cool/viscous isn't the answer. Emulsion that is too thick comes with its own set of problems. The print to the left is the base K-layer for a silvergum print. To hold up to the abuse it will take by the time five layers of gum and pigment have been applied, not to mention the 45 minute soaks in water between each layer of color, the dried emulsion has to be tough as nails — and it is. The emulsion was hardened by the addition of glyoxal right before coating. Along the bottom of the print, you can see a side effect of that hardening. The outside edges of any coating are almost always thicker than the main body. When emulsion is hardened, the processing chemicals have a hard time penetrating, especially the fixer. Over time, after the print is processed and back in room light, the emulsion in the thick areas will darken. This is usually not a problem. You just trim off the uglies — well worth it to get 'tough as nails' emulsion. So, why not just harden every emulsion as a matter of course? As throughout this business, the answer comes down to cost/benefit and the simple truth that one size never fits all. Unhardened emulsion is easier to tone. It is easier to spot (a.k.a. retouching, the correction of flaws by painting with dyes). The only real tradeoff is the need to be careful during processing. Unhardened emulsion is tender. You'll need to handle it gently and at the corners all the time it is wet. You won't want to squeegee the print — rather, just pull it out of the last wash water and hang it by a corner. When it's dry, it's no longer tender. But, most important for beginners is that random patches of thicker emulsion (inevitable!) won't necessarily ruin a finished print. Your processing chemistry will penetrate even the thickest areas. |

This isn't to imply that thick emulsion is without problems even if it's unhardened. It may not turn out bronze uglies, but if it's thick enough, it will dry with a very stubborn curl that can refuse to flatten even in a contact printing frame. In any area where the negative doesn't make tight contact with the negative, you will see out-of-focus areas on the final print. |

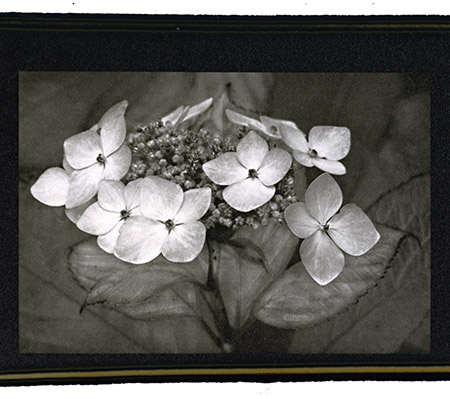

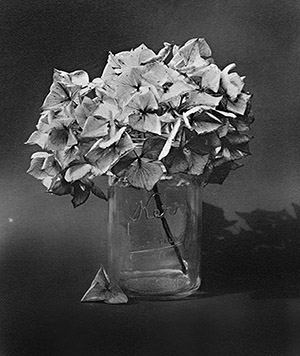

Air bubbles happen from time to time. If you have a lot of them, you may need to add a drop or two more Photoflo, but most likely an adjustment in the way you coat will solve the problem. (Experience, I'm afraid.) If you see them immediately after coating the sheet, you can get rid of them with a light mist of Everclear. I keep a small spritz bottle of it handy. The bottle came with a free sample of lens cleaner when I bought my eyeglasses. It delivers a perfect, fine mist. Fortunately, a dried bubble is easy to see under safelight, so you can often trim the paper to avoid it. If nothing else, the sheet can be used for test strips and prints. 'Long Term Memory' (the dried hydrangeas in a canning jar) is a contact print of a whole plate format (6.5 x 8.5 inches) glass dry plate, contact printed on our first recipe. |

|

One last thing—and as much a sanity alert as a troubleshooting tip: |

There is one big component of our art that is out of our control—watercolor paper. No matter how high the quality, watercolor paper is made for watercolor painters, not photographers. A couple of years ago, my emulsion started forming big, blistering bubbles during the processing. Absolutely perplexing. I made a half dozen batches of emulsion, with different changes each time, and nothing fixed the problem. It wasn't until weeks had gone by that I realized I was using a new lot of paper. Fortunately, I had a few sheets left from previous lots and those coated perfectly. Turns out Fabriano had changed the sizing recipe for their Artistico paper. I put the remaining sheets in storage and switched to Arches. I've had perfect luck with it until the last package of 90 lb HP. On random sheets, great blotches and tracks of mottled fading appeared—but not until the very end of the wash cycle. Coming out of the fix and the first 15 minutes of washing they looked perfect. I admit a silent "what the ...?!" crossed my mind. Happily, it seems I've run through the sheets that somehow (??) got contaminated with something (??) at the factory. Some things are probably puzzles never solved, so best to take a deep breathe, smile for the love of a good mystery and move on. |

|