16. Plain Silver BrI Dry Plate Emulsion—The Recipe

An adaptation of Kodak Publication No. AJ-12, 1969 Revision,

by Denise Ross for The Light Farm, 2013.

The recipe is divided into three steps. They can be completed one after another on the same day, or divided into separate work sessions, according to time available. The steps are precipitation, washing, ripening, and coating. In addition to the main emulsion making steps, time must be allocated for glass plate blank preparation, and for drying the coated plates.

Before each step, line up the tools and materials required. The precipitation techniques are the same as for gaslight paper — hand mixing or magnetic stirring. Plan according to your preference.

A Note about KBr: Potassium bromide almost always comes in large, rock-hard pellets. These can take a long time to dissolve or dissolve incompletely, and if there are undissolved pieces during precipitation, you could get black "slugs" or "sunspots" on the final negative. I suggest that you have a mortar and pestle dedicated to KBr grinding. I grind the KBr I use to a fine powder. A fine powder also makes weighing out easier. Keep the mortar and pestle in a plastic bag between uses. Store the ground KBr in an airtight jar. A canning jar with a tight lid is perfect.

Step One: PRECIPITATION

Pre-heat a 55°C waterbath.

Salted Gelatin

In a 1-cup Pyrex measuring cup or 250 ml beaker, thoroughly dissolve together:

- Distilled water ..... 45 ml (45 g)

- Potassium bromide (KBr) ..... 5 g

Add:

- Gelatin ..... 2 g

Cover, bloom 15 minutes, and then place in the waterbath. Let sit 30 minutes, making sure the waterbath temperature comes back to 55°C. Stir in:

- 10 % Potassium iodide solution (KI) ..... 1 ml (20 drops)

While the Salted Gelatin is melting and coming up to temperature prepare the Second Gelatin and the Silver Solution.

Second Gelatin

Mix together, cover, and set aside:

- Distilled water ..... 25 ml (25 g)

- Gelatin ..... 5 g

Silver Solution

Dissolve together:

- Distilled water ..... 45 ml (45 g)

- Silver nitrate ..... 5 g

Right before precipitation, temper (warm) the silver solution in a very hot small waterbath. My method is to boil an inch of water in a Pyrex cup in the microwave. My microwave is in the kitchen on the other side of the house. By the time I get the cup and hot water back to the darkroom, it's the right temperature. Warming the silver solution helps cut down on any "pepper" problems (grains of silver that develop-out black even without exposure to light). Again, a loose analogy to cooking: if you are making a custard, tempering the milk and eggs reduces the chances of curdling.

CAUTION: At all times when handling silver nitrate, be very careful. Silver nitrate is a powerful oxidizer and stains anything organic it comes in contact with. If you get stains on your skin they cannot be washed off. They will be part of your skin for weeks. If you get silver nitrate in your eyes, the damage could be blinding. Don't be afraid, just be careful. Silver nitrate is no more hazardous than many common household cleaning chemicals. Bleach and drain cleaner come readily to mind. On a happier note, there are no hazardous fumes involved with a plain silver nitrate solution.

- Set a timer for 10 minutes.

- GO TO SAFELIGHT.

- With constant, consistent stirring, add the silver solution to the salted gelatin at a rate of

1 teaspoon (5 ml) every minute until the solution is gone. - Stir until the end of the 10 minutes.

- Let the emulsion sit in the waterbath, without stirring, for an additional 10 minutes.

- If you are using a magnetic stirring bar, remove it with a plastic fork.

- Add the second gelatin. Stir in thoroughly.

- Pour the emulsion into a ziploc-style plastic sandwich bag, seal, and place in a cold, lightproof container.

- Cover to exclude all light and refrigerate for a few hours to a few days.

Step Two: WASHING

Have ready two thermos containers—one for washing and one for holding ice water, a potato ricer (or noodler of your choice), washing bag, a small rubber scraper, and the lightproof container (still covered) of emulsion, plus a supply of water if you aren't doing this next to running water. Almost fill the washing thermos with ice water. Position the washing bag over the mouth of the thermos. Set the bowl of the ricer in the bag and ice water. Note: No matter how you are noodling, the idea is to do it into the ice water so that the shreds stay cold and separated.

- Set a timer for three minutes.

- GO TO SAFELIGHT.

- Open the container with the plastic bag of emulsion. The emulsion will be a cold, rubbery ball. Pull out the ball (in one piece or several) and put it in the potato ricer. Press the emulsion through the ricer into the ice water.

- Scrape all of the emulsion clinging to the ricer into the washing bag.

- Tie up the washing bag tightly, and dunk it up and down in the ice water for three minutes.

- Take the bag out of the ice water and give it a gentle squeeze.

- Pour out the ice water and replace it with fresh. You can catch the pieces of ice in a colander and reuse them.

- Repeat five times for a total of six (18–20 minutes washing).

- After the last washing take the bag (which will be about doubled in weight) and squeeze it in the ricer. Squeeze firmly (but not hard enough to burst the bag!) Squeeze until little-to-no water is coming off. Pat dry with a clean towel.

- Dry out the lightproof container and place the washing bag in it. Cover securely and refrigerate until it's time to ripen and coat. You can do this immediately if you are ready to go. The time the emulsion is hardening in the refrigerator is plenty of time to stage coating. Or, you can refrigerate the shreds up to several days. Note: Never freeze emulsion at any stage.

Emulsion washing is my favorite part of the making process. In the following video clip I'm running through a condensed version. I skipped scraping the noodles off the ricer. The trouble I had with the drawstrings on the washing bag is a perfect illustration-by-accident of the best thing about emulsion washing: Short of dropping everything on the floor, nothing that matters can go wrong. The ice keeps the water at a perfect temperature. The timing is loose. If the phone rings, you can leave things sitting for a few minutes. I put some music on and just chill (pun intended!)

Step Three: RIPENING

Have your plates ready for coating and a pre-heated 55°C waterbath.

GO TO SAFELIGHT.

- Scrape the noodles out of the jelly bag into a 400–500 ml/~2-cup container that fits with your waterbath.

- Stir in 1 teaspoon (5 ml) Everclear.

- Set the noodles in the waterbath for 45 minutes. Don't stir. Alternatively, you can stick a thermometer in the emulsion and pull it out of the waterbath when the temperature reaches 55°C. If you are using kitchen gelatin, reduce the waterbath temperature to 50°C and pull the emulsion when it reaches that temperature.

- Take the container of emulsion out of the waterbath and set it in a bowl of cool water so that the water comes up to about the level of the emulsion.

- Very slowly and gently stir the emulsion with a plastic spoon until the temperature reaches whatever coating temperature your experience tells you is best. This can be from the low-to-mid 30s°C to the lower 40s°C.

- Coat.

Note: Kitchen gelatin is considered active, i.e., it contains components that could cause fog if the emulsion is overheated or heated too long. So-called "photographic gelatin" is inactive. Unless otherwise specified, it has been treated to remove the components, primarily sulfur, that affect emulsion characteristics. Using it reduces one element of uncertainty from the process, but with plain silver emulsions, photographic gelatin is not absolutely necessary.

Step Four: COATING

Emulsion can be coated on either glass or film.

Coating on Glass

Dry plate negatives are emulsion coated on glass sheets, sized to fit any number of large format cameras. Go here for a description of the technique. (It is also covered in The Light Farm book.)

Coating on Film

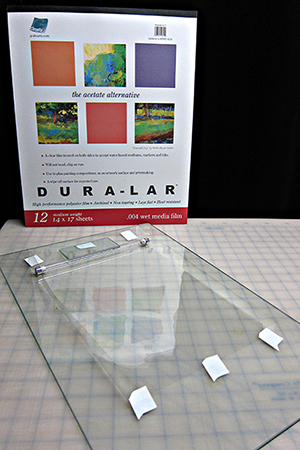

Grafix Dura-lar Wet Media Film is the perfect substrate for handmade film. It's the "wet media" aspect that makes it work. Emulsion is water-based. Untreated polyester film (PET) is naturally hydrophobic (repels water). Dura-lar Wet Media Film has been treated ("subbed") to accept water-based coatings.

Coating techniques are covered in The Light Farm book and here.