Plate Prep and Coating |

| Back to 'Dry Plate Photography Index' | Previous | Next |

The Basics |

|

The key to a beautiful dry plate is careful glass preparation. This means a clean surface and smooth edges. I have good luck cleaning glass with paste of calcium carbonate (here), Everclear, and Seventh Generation 'free & clear' liquid dishwashing detergent applied with a soft nail brush, followed by a thorough tap water rinse and then a final rinse in half distilled water and half Everclear. After a plate is clean, I never again touch it with bare hands. William Winkler has a more elaborate cleaning system (here) that works even better to help emulsion adhere to glass. |

|

Emulsion has a tendency to pull away from the edges of the plate, even if the glass is clean. This is rarely a problem. Edge chips are another matter. Note the bottom edge of this dry plate and the close-up of one of the chips in the next illustration. |

|

Enlarged crop from the image above, showing an emulsion flaw that formed around a chip in the glass. |

|

|

|

A smooth, rounded edge is easy to achieve by hand. This piece of glass has a raw, snapped edge (left) and a smoothed edge. An excellent way is with a set of 3M Diamond Pads in five mesh sizes. Start with black (120 mesh) and move through all the grits — Red (200), Yellow (400), White (800) and Blue (1800). The edge will end up baby butt smooth in only a couple of minutes. Wear a dusk mask and gloves and watch where the glass dust falls. |

|

The 3M pads are available individually or as a set. Follow the 'Hand Tools' link at the top of

this page.

and look toward the bottom of the page.

If you are planning on making a lot of plates, there a number of electric grinders available. The best advice is to find the nearest stained glass supply store and let them help you out. |

|

Even with perfectly smooth edges, few finished plates will look like a piece of commercial film. I think this is a thing to celebrate. Consummate craftsmanship can still show the hand of the artist. Contact printing is a way to go. Everything shows, warts and all. That's part of the attraction of a handcrafted print. What usually happens with dry plates is a slight emulsion thinning around all the edges. These thin areas naturally print out darker, making a natural border around the print, masking for the most part any flaws around chips. This print is do-it-yourself from start to finish. The dry plate was contact printed on handmade baryta paper ('Warm ♥ Emulsion' coated on Rives Lightweight watercolor paper coated with 'TLF Baryta'. |

Plate Coating - The TLF System |

|

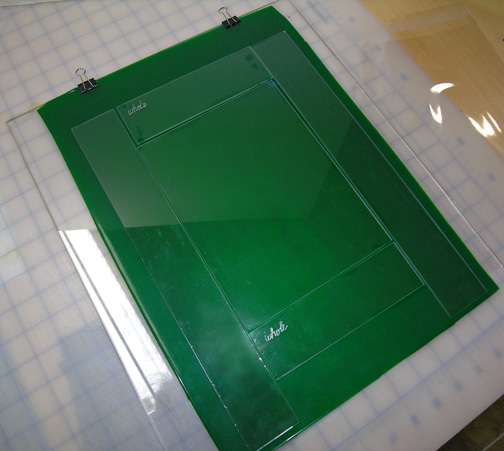

Simple-minded soul that I am, I've devised a plate-coating system that is almost identical to paper coating. The key is extending the coating area so that the emulsion well and coating rod make contact with glass along its entire length and the plate is flooded with emulsion edge to edge. This is easily done by surrounding the plate with strips of glass the same thickness as the plate. Leave about a 1/16th-inch gap between these 'guide bars' and the plate. This makes a channel that the emulsion spills into, forming an emulsion band around the edge of the plate. (The guide bars are reusable, as are any plates that you don't want to keep. Very frugal, this dry plate stuff!) The entire glass assembly must be at least 1/2-inch wider than the coating well and long enough that the coating pull starts and stops off the plate. The nifty tool that makes this trick work is a thick silicone cookie sheet. (This isn't to be confused with a thin, smooth silicon baking mat that is meant to replace parchment paper on a metal cookie sheet.) Look for the heavy-duty, slightly spongy varieties. These often come with a metal rim that must be cut off or the sheet will not lie dead flat on the acrylic. The silicon grips the glass so that it can't budge while you are coating, but still allows easy removal after the emulsion is dry. I bought my sheets at a mall cooking store. The brand name was le gourmet chef, but their website doesn't carry sheets like I bought, so I offer what looks like a good bet (here). My advice, though: Don't order online. You'll want to know for sure the sheets are at least 1/16th-inch thick and 'grippy'. (Modified on 3/5/09: I have found an excellent source for silicon sheet material from Rubber-Cal in Anaheim, CA. http://rubbercal.com/Silicone_CG.html. The 1/16" thickness is working very well for me.) |

|

Materials required:

|

|

|

Secure the silicon sheet to the acrylic sheet with the binder clips. Center the plate and arrange the glass guide strips around it, leaving a slight gap. (This allows the emulsion to flow over the edges of the plate and form a nice protective rim of emulsion.) Spritz the glass with a bit of Everclear (don't flood things) and applying a fair amount of pressure, rub the glass. This accomplishes two things: 1) a final cleaning and 2) it forms a good contact between the glass and the silicon. Center the well, emulsion gap at the back, straddling the space between the top guide strip and the plate. Lean the coating rod on the back (gap side) of the well. (Note: In order to show the top space, this illustration has the well set too far up. It should be down just a bit so that you can see the space between the top guide bar and the plate as you look down on the inside the well.) |

|

|

Take the time to do perfect leveling, front-to-back and side-to-side. The first thing I do when I'm preparing to coat is line up the plates. (The set-up shown is for coating 4"x5" plates. It works great to coat two per sheet, side-by-side.) When the emulsion is ready to coat, I take one sheet at a time from the lineup to the coating platform and then carefully return it a few minutes after it's been coated. The emulsion does its first drying step back in the line-up. |

|

T0 COAT: Fill your syringe with the right amount of emulsion. I use 20 ml for a 5"x7" plate, and 25 ml for two 4"x5" plates, coated side-by-side. Stick the syringe tip in the well, at the center, and quickly and smoothly depress the plunger. Immediately, pull the well and puddle pusher assembly down the length of the glass, ending on the bottom guide bar. If it looks like any part of the channel around the plate is overtopping with emulsion, carefully suck it back up in the syringe and return this to your emulsion pot. I plan on having a video-short of this step sometime in the not-too-distant future, but for now, believe that it is easy and that a little practice will set you right up. |

|

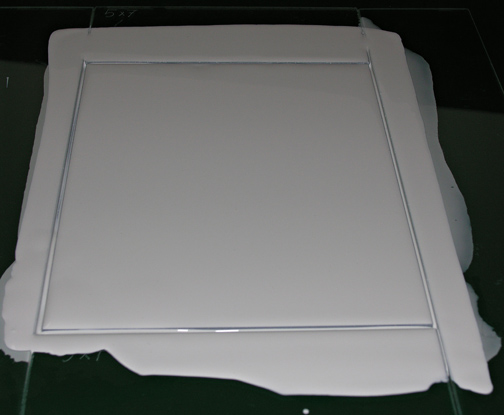

Acrylic gesso, diluted with water to the consistency of heavy cream, is an excellent coating practice material. It handles almost identically to emulsion. One note of caution, though. It's messier, by far, than emulsion and harder to clean from the coating tools. Make sure you never let it dry on the well or puddle pusher. The good news, of course, is that you can cheaply practice coating in the light. |

|

After the coated plates have dried enough so that there isn't a sheen left (this is easy to see under a safelight), there is still one drying step left, because any emulsion that seeped under the glass is still wet. Starting with one of the long vertical guide bars, lift the bar up from its clean outside edge, moving toward a 90º angle between the bar and the plate. The emulsion that has dried in the channel will look and feel like a hinge. Carefully bend the guide bar back and forth until this hinge breaks. You want to avoid pulling any emulsion off the plate. Repeat this step around the plate until you've removed all four guide bars. Get a hand under the silicone sheet and lift. This will let you easily get a finger under one of the plate corners and let you lift the plate off the silicone without touching the emulsion on the plate surface. Place the plates (face up) on a fiberglass or plastic screen to finish drying. How long this takes depends on the humidity. After the plates are dry, you may need to remove excessive dried emulsion from around the edge of the plate or you will have trouble fitting the plates in some holders. I use a razor blade, being very careful to leave some dried emulsion on the edges. After your plate is exposed, processed and dry, you can remove any emulsion on the back of the plate with a damp rag, being careful of course to keep the emulsion on the image side dry. Note: Any dust and debris blowing around in the air while the plates are drying will end up a permanent part of the plates. Do what you need to do to assure that the air in your drying area is as clean as possible. Having said that, there is no need to be obsessive. It takes a fairly large particle to show up on a final print. Our predecessors learned to spot their negatives and prints. |

Coating Big Plates - The ULF Option |

|

It can be a challenge to pour-coat plates larger than 4"x5". The TLF coating system allows consistent coatings for much larger plates and any format. My Indian panoramic camera (here) shoots 6"x15" plates, with the option of a 5"x12" insert. The print below is from a 5"x12" plate. I used the same coating well that I use for 5"x7" plates. The only new item needed was longer side bars (please see the above sub-section.) The plate was photographed on a light table with a Pentax K20 camera. The PS tools used were limited to invertion, an unsharp mask, curves, and a bit of burning and dodging. There was no spotting or blemish control of any kind on the final print or on the original file of the plate (shown below - both small and very large. |

|

|

|

An enlarged crop of the above image. |

|

|

The original dry plate (no PS). It was a dark day. In fact, it started raining while I was exposing the plate. A pop-up enlargement is available below. |

|

|

Pentax K20 color record. I re-staged the animals an hour later when the weather cleared. |

| If you would like to examine an extreme enlargement of the plate, please go here. Be forewarned that is over half a megabyte in size, and could take awhile to download with slower connections. The file of the negative is completely raw and unmanipulated (except camera resolution sharpening for web display). |

| Back to 'Dry Plate Photography Index' | Previous | Next |

Copyright © The Light Farm |